Sustainability

We care about the planet

As a part of society, New Terracotta wants to contribute to improve the lives of the current and future generations.

First and foremost, by manufacturing beautiful, high-quality tiles that are guaranteed to last for centuries and also by using part of our profits to make an essential contribution to the well-being of our employees, community and the environment. Corporate well-being has been part of our ethos since day one. In fact, sustainability actually pushed the founders to create a 100% handmade eco-friendly terracotta factory in a low-density rural area in central Portugal.

Social Sustainability.

The People Home Factory.

At New Terracotta, a comfortable atmosphere, a people-oriented approach and a focus on integrity take centre stage. All our people are motivated and given the opportunity to develop their skills to the maximum of their potential and take responsibility. We are truly committed to fostering an inclusive culture in which diversity is recognized and valued.

The pink factory in the forest which connects people to nature. Our 90 employees are active ambassadors who shape their own future in a stimulating, safe, healthy and beautiful environment with minimum stress. The lush forest that greets visitors to New Terracotta factory comes as such a contrast to the rest of the industrial parks.

Corporate Social Responsibility.

Making a little difference.

Since the company’s establishment in 2014, it has been of great importance to play a significant role in making a positive contribution to the society that surrounds us.

Verde Acreditar.

The importance of 33.600 tiles.

Acreditar is an Association of national reference in guaranteeing the rights and promoting the quality of life in the area of pediatric oncology. Put together in 1994 with the mission to tackle the changes that childhood cancer imposes, providing everybody the promise of support at a time of uncertainties.

Now with four homes built in Portugal – Lisbon, Funchal, Coimbra and Porto – the Casa Acreditar is a privileged space, fully dedicated to accommodating children undergoing cancer treatment, as well as their closer family. Bringing comfort, peace and a touch of ‘normality’ into these lives and we, New Terracotta, had the privilege to give a little bit of us to this great institution.

Casa Acreditar Porto.

This particular project, Casa Acreditar in Porto, with 4 stories and 1707m2, built on a land adjacent to the IPO and close to the São João Hospital, this house, home for 16 families, has 16 bedrooms with their private bathroom, 3 common rooms (one for parents, one for children and another for young people), a communal kitchen with five modules, a laundry and outdoor recreation areas.

Designed by ALA.rquitectos (at the time – Atelier do Cardoso), we were commissioned by the architects, Mafalda Ribeiro Ambrósio and João Gomes Leitão, to develop a special glaze for the exterior facade of the building. We took this assignment to heart, coming up with a glaze with highly variable hues, mimicking the surrounding spaces and heterogeneity of the families themselves. We named it Verde Acreditar.

“Acreditar” – meaning to believe

www.acreditar.org.pt

Environmental Sustainability.

The Slow Eco-friendly Tile.

At New Terracotta we are dedicated to minimise our environmental impact. It has always been a central part of our culture and it’s in everything we do.

Clay as a raw material.

Tiles are exclusively made of natural components, such as clay, water, pigments and additives derived from natural sources. Clay, the basic raw material used for our tiles, is almost infinite.

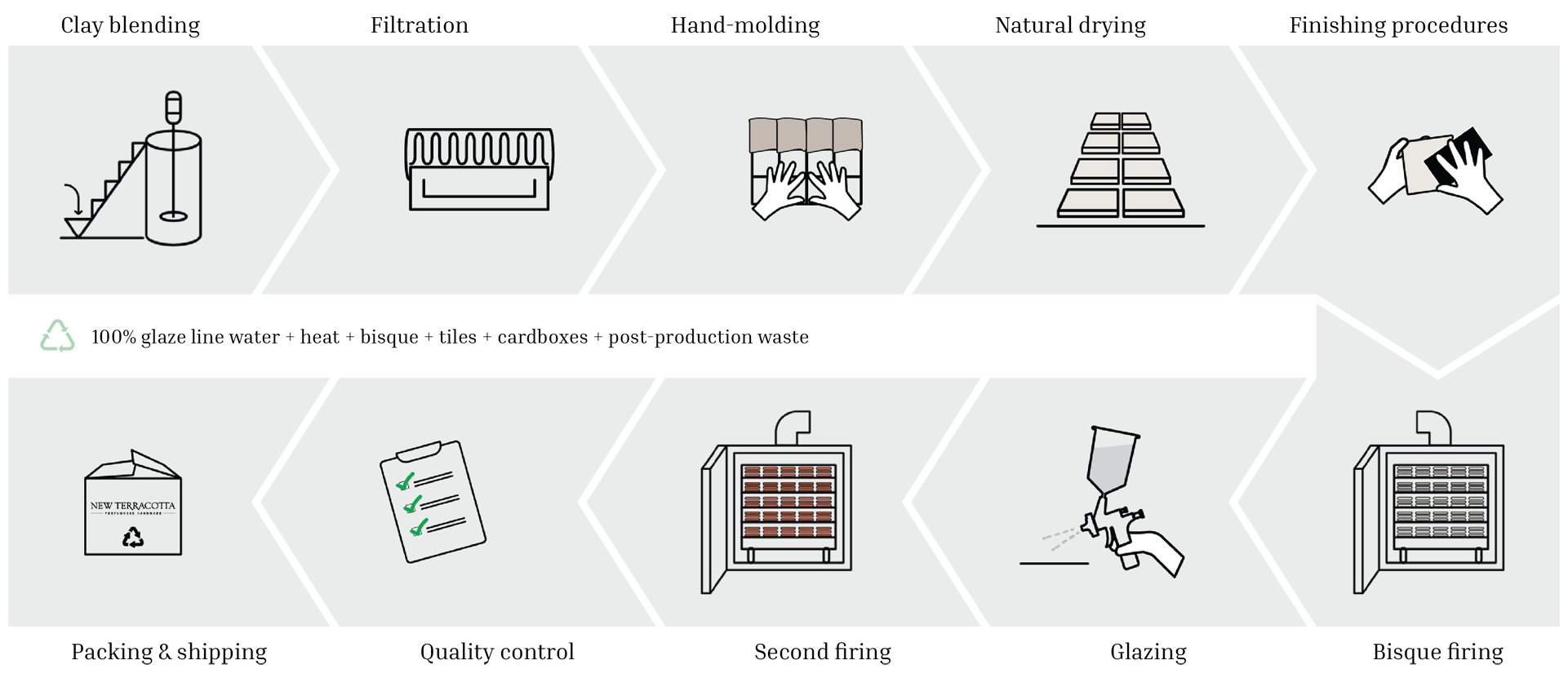

Minimal waste.

Clay scraps and imperfect pieces produced are re-mixed and put back in our clay body. All water used in the process is recycled and the liquid waste glaze is reclaimed. During production, heat captured from the kilns is redirected to dry tiles prior to firing, meaning that the heat energy generated is used twice. Our production contains 40% recycled materials.

Environmental impact.

The only significant environmental impact during the production phase stems from the energy used in firing. In order to reduce the carbon emissions, our suppliers are located within 80 km of our factory.

Zero VOCs.

Tiles are inherently inorganic, emitting zero VOCs. VOCs are harmful gases that can cause headaches, nausea, and nose, eye and throat irritation.

Durability and maintenance.

Tiles have a very long lifespan, lasting for hundreds of years without maintenance. Tiles are used untreated and are maintenance-free. Unlike other building materials, glazed tiles do not need to be treated with hazardous chemicals that have a detrimental impact on the environment.

Demolition, disposal and recycling of crushed tile.

Clay does not cause environmental problems during demolition or disposal. Tiles can be crushed, recycled and reused.

Thermal conductivity.

Ceramic tiles have a negligible coefficient of thermal conductivity, thus being an excellent thermal insulator.

Flame resistance.

Tiles are non-flammable.Ceramic does not burn or spread fire and its surface does not exude any type of toxic gas or vapors during the presence of flames.

Recycling at New Terracotta.